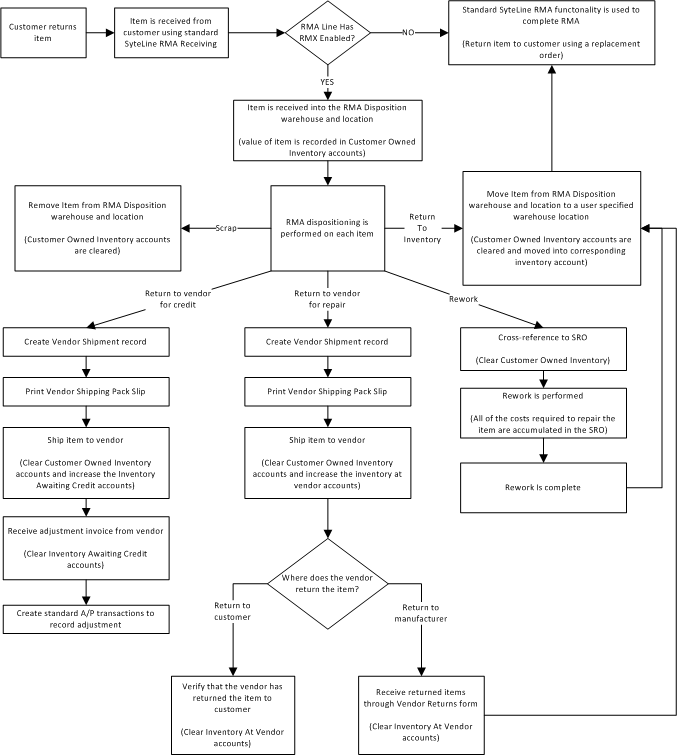

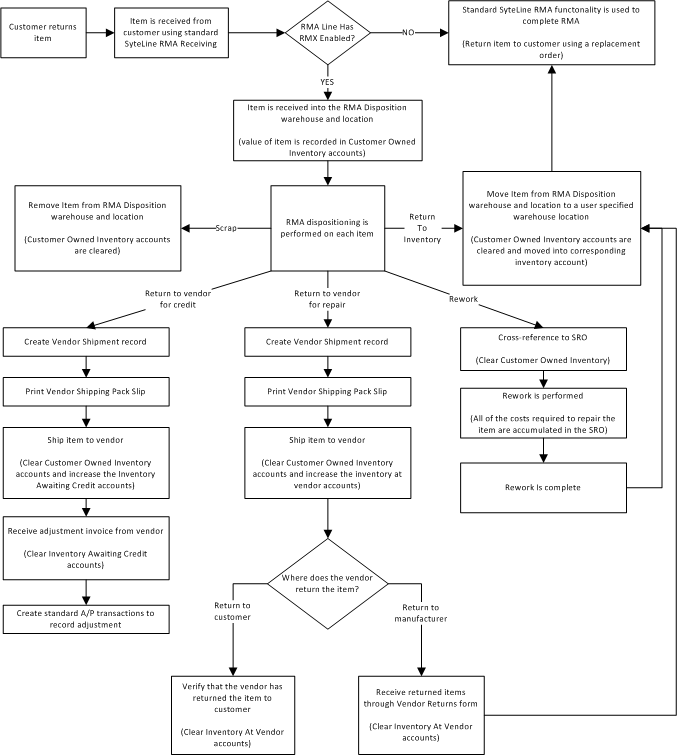

Extended dispositions give you more options after materials are returned from a customer. In the standard process, materials are received from the customer, placed into inventory, and a replacement order is issued to the customer if the item needs to be replaced. After the material is returned to the customer, you record a disposition code for the item that was returned. This disposition code is used mainly for reporting.

If Use Extended Disposition Process is selected for an item on the RMA Line Items form, you can specify multiple user-defined disposition codes for one RMA line item. These codes identify the next steps for the returned material. Each disposition code has one of these disposition types:

If Use Extended Disposition Process is selected, the returned item is initially placed in the Disposition Warehouse and Location that is specified on the RMA Parameters form. The item remains in that warehouse until dispositioning is completed. See the process flow below.

On the RMA Line Items form, Disposition tab, you can optionally use the Serial Number field to preassign a serial number for a returned item.

Use the RMA Vendor Shipping form to ship items where the disposition is set to Return to Vendor for credit or for repair. If the return is for credit, you are prompted for the amount of credit and an adjustment voucher is created. If the return is for replacement/return, the system tracks which items are due back from the vendor.

Use the RMA Vendor Returns form to receive items that the vendor has repaired and returned to your company.

This diagram shows the process flow for returned items to be dispositioned;

RMA Extended Disposition - Accounting Information

Setting Up RMA Extended Dispositions